Stone Commercial Lintel

Quite a few commercial buildings use stone or concrete lintels because they add a nice look to the exterior of the building. They are not as strong as steel lintels and they don’t rust, but you still need to inspect them. Stone or concrete lintels will actually deteriorate over time primarily due to water pooling. This will slowly eat away at the lintel and eventually lead to failure.

I-Beam Lintel

The I-Beam lintel is one of the strongest designs out there. They disperse weight in a way that allows for larger openings. Commonly used in applications where the opening is larger than 8’0”. Inspection and maintenance is very important because of the load this type of lintel can handle. Inspection will be limited to the underside of the beam, but it will be able to give you a good idea of what is happening in the hidden sections. If pitting is visible action should be taken immediately. A professional will remove the elements that are causing the pitting and then treat the exposed area with a rust-inhibiting primer and then a final coating. This will dramatically extend the life of the lintel.

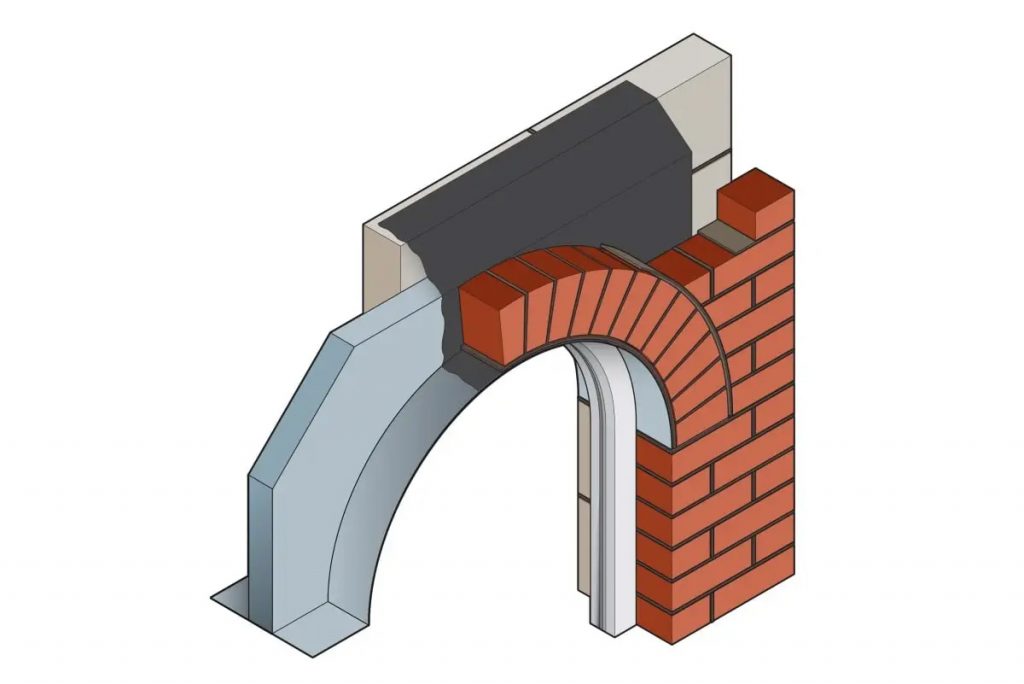

Arched Lintel

The most common arched lintel will have a box hidden inside the arch. It is used to disperse the weight while still providing the needed support. There are Concealed Lintel Systems available for arches also, those are generally used when creating an arched entry on a security wall or walkway. Due to the design, water pooling is only an issue when there are mortar failures. It is important to inspect the mortar above the arch to ensure water isn’t getting into the hidden structure.

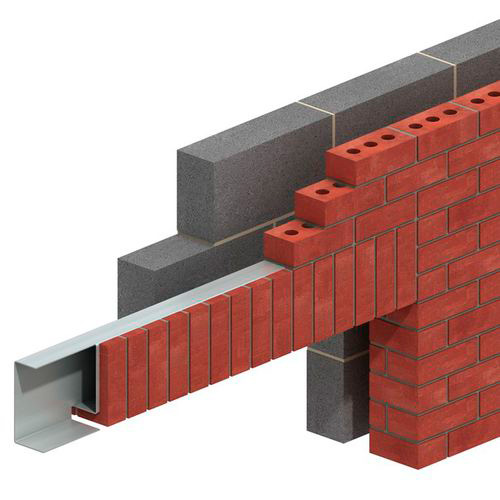

Stainless Steel Lintel

Stainless steel lintels are a low-maintenance option that has a vast number of designs. They come in numerous different shapes and sizes and are the go-to for bespoke applications. Stainless steel is very strong and extremely resistant to the elements. Yearly inspections and basic maintenance are still necessary.

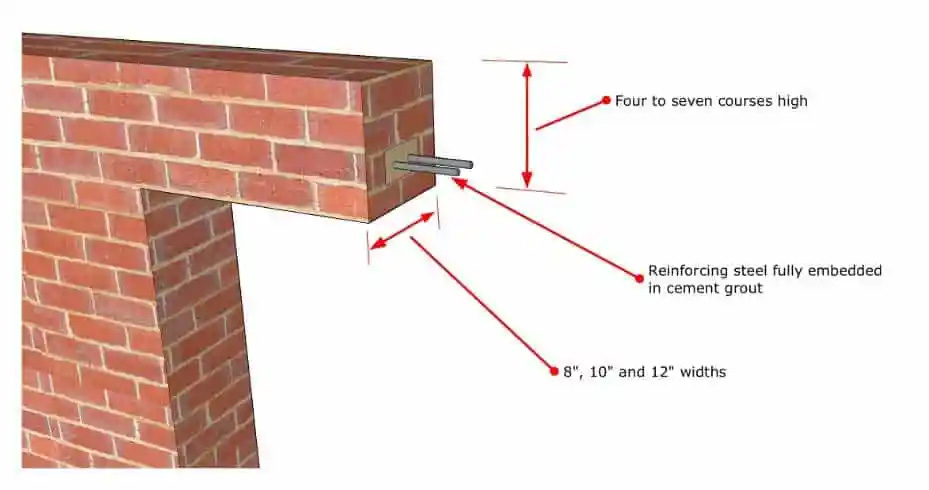

Reinforced Brick Lintel

Brick lintels are not commonly used because of the weight limitation and short span allowance. When restoring historic buildings a brick lintel is sometimes needed. This is when you would use reinforcement bars to enhance their strength and cover longer distances. Mortar is inserted to fill up the gaps and stirrups are installed in every third vertical joint. Just like normal brick applications, the mortar joints should be monitored and receive attention when deterioration is noticed.

Reinforced Concrete Lintel

Reinforced concrete lintel is strong, durable, fireproof, and easy to construct. The amount of internal reinforcement depends on the span. This type of lintel is commonly found in older warehouses. Like any concrete, it is susceptible to water erosion. But due to the 1:2:4 concrete mix commonly used it doesn’t happen as fast as other concrete applications.

Here at N&M Restoration, we have experience working with the commercial lintels used in these examples. Our experts are capable of examining your current lintels and identifying any issues you might have. We will help you spot an issue before it becomes an overwhelming expense. Give us a call today at 248.924.9798 to schedule your free estimate.